Key Takeaways:

- Multi-layer PCBs are essential for modern electronic devices due to their enhanced performance and reliability.

- These PCBs allow for compact product designs and higher efficiency by providing more space for integrated circuits.

- Advanced multi-layer PCB design techniques can significantly improve signal integrity and circuit connectivity.

Table of Contents:

- Introduction

- Understanding the Structure of Multi-Layer PCBs

- Benefits of Multi-Layer PCBs in Complex Electronics

- Enhancing Performance Through Layer Management

- Applications of Multi-Layer PCBs

- Conclusion

Introduction

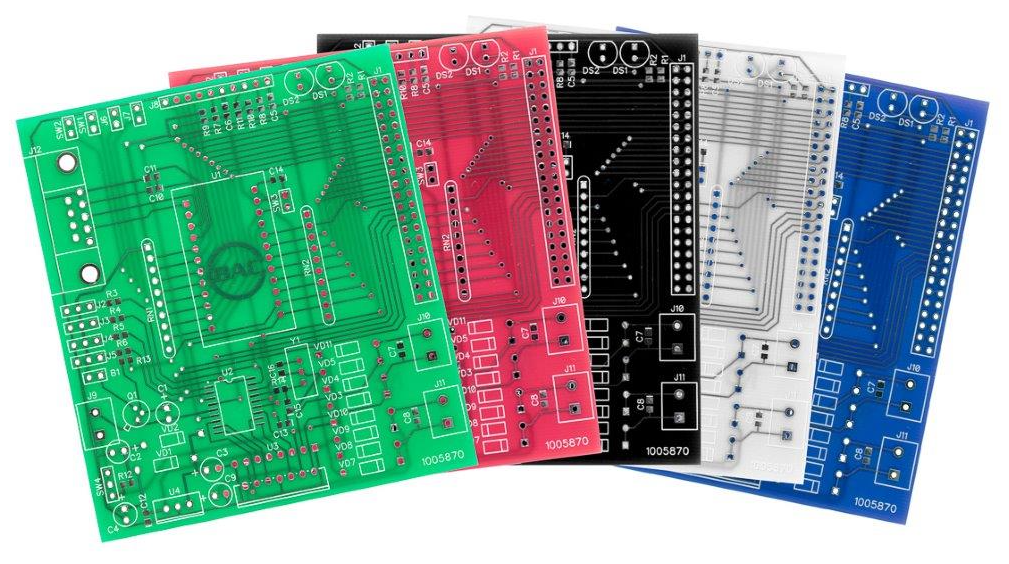

In the rapidly evolving world of electronics, the demand for more compact, efficient, and powerful devices is ever-increasing. Developing multi-layer Printed Circuit Boards (PCBs) is at the heart of meeting these demands. They represent a significant evolution from their single-sided counterparts, providing a backbone for today’s complex and high-performing electronic systems. Multi-layer PCBs not only solve the challenge of space limitation but also enhance the functionality and reliability of electronic devices across various industries. As technology becomes more sophisticated, the role of these PCBs continues to grow, becoming indispensable in developing and manufacturing advanced electronics.

Understanding the Structure of Multi-Layer PCBs

To appreciate how multi-layer PCBs improve performance, it’s essential to understand their structure. These PCBs consist of multiple layers of conductive material separated by insulating materials. The layers are composed of copper, which transmits signals within the board, while the insulators, commonly made of fiberglass or other dielectric materials, provide structural integrity and prevent electrical shorting between layers. This unique structure allows multi-layer PCBs to support a higher density of components and circuits, making them particularly suitable for complex and compact electronic designs. Multi-layer PCBs start with a core substrate, with additional layers built upon it. Each layer is carefully etched to create a precise pattern of pathways. These pathways are then laminated together to form a unified board. Stacking up to 40 layers, these PCBs provide the necessary space to incorporate various circuits, increasing the board’s overall functionality. This design facilitates the integration of complex components, including microprocessors and other integrated circuits, which demand elaborate circuit frameworks. Incorporating sophisticated design services such as Orcad PCB New England can optimize this layer management, ensuring efficiency and performance.

Benefits of Multi-Layer PCBs in Complex Electronics

The benefits of multi-layer PCBs are diverse, contributing significantly to the efficiency and compactness of modern electronics. One of the most notable advantages is their ability to save space. With multiple layers, electronic circuits can be spread across the stacked layers rather than confined to a single surface, paving the way for smaller device footprints without compromising functionality. Furthermore, multi-layer PCBs enhance electrical performance by reducing interference between circuits. The proximity of power and ground planes within the stacked layers allows for efficient signal distribution and minimal path length, which helps lower inductance and capacitance effects. This design minimizes issues such as crosstalk and electromagnetic interference, which can degrade signal quality in high-speed applications. Another significant advantage is the improved thermal management that multi-layer PCBs offer. Including dedicated thermal vias and conductive planes within these boards facilitates better heat dissipation, which is critical for maintaining the longevity and performance of high-power components. This aspect is especially crucial in complex electronics where efficient thermal management correlates directly with reliability and durability.

Enhancing Performance Through Layer Management

Multi-layer PCBs facilitate enhanced performance primarily through strategic layer management. This entails a meticulous layout of power and ground planes, signal traces, and component placement to optimize the board’s functionality. The precise arrangement and layering of these elements improve signal integrity, which is crucial for maintaining the performance and reliability of high-frequency applications. In addition, technology is pivotal in connecting different layers within a multi-layer PCB. These vias serve as conductive pathways that link the circuits across layers, ensuring complete and efficient connectivity throughout the board. Opting for technologies like blind and buried vias further enhances the board’s space efficiency, as these vias connect internal layers without traversing the entire board, preserving the top and bottom layers for component placement. The strategic use of layers also allows for better segregation of analog and digital signals, preventing interference and ensuring cleaner signal paths. This aspect is vital in mixed-signal environments where digital noise can easily corrupt the integrity of analog signals. Effective layer management thus plays a pivotal role in the precise and high-performance operation of electronic devices that rely on multi-layer PCBs.

Applications of Multi-Layer PCBs

Multi-layer PCBs find applications across a broad spectrum of industries, each benefiting uniquely from their advanced capabilities. In consumer electronics, they are foundational in developing smartphones, tablets, and laptops, where the demand for compact design and high functionality is paramount. The ability to manage complex circuitry in limited space makes multi-layer PCBs an ideal solution for these applications. The automotive industry extensively integrates multi-layer PCBs within vehicle control units, navigation, and infotainment systems. These PCBs support the intricate electronic architectures required for modern autonomous driving technologies, enhancing vehicle performance and safety systems. Multi-layer PCBs are indispensable in telecommunications routing and data transmission devices, facilitating faster and more reliable internet services. With the ongoing rollout of 5G technology, multi-layer PCBs play a crucial role in managing the increased data speeds and bandwidth requirements—furthermore, the medical sector leverages multi-layer PCB technology to design and operate diagnostic and monitoring equipment. Devices like MRI machines, heart monitors, and other complex medical instruments rely on multi-layer PCBs’ reliability and precision, contributing to better patient outcomes and enhanced healthcare services.

Conclusion

As technology continues to evolve, the significance and application of multi-layer PCBs in complex electronics cannot be overstated. These boards are pivotal in enabling the compact, efficient, and high-performing devices that define our modern technological landscape. By accommodating extensive circuitry in a reduced space, they enhance the design and improve electronic systems’ overall functionality and reliability. The advanced design capabilities of multi-layer PCBs ensure their continued relevance in a future where technology becomes more integral to our lives. Their ability to meet the rigorous demands of modern electronics means that multi-layer PCBs will remain at the forefront of innovation, driving advancements across diverse industries.